parameters

| NO | Description | Parameter | |||

| 1 | Model | AKM1325C2 | AKM1530C2 | AKM2030C2 | AKM2040C2 |

| 2 | X,Y,Z Working Area | 1300x2500x250mm | 1500x3000x250mm | 2000x3000x250mm | 2000x4000x250mm |

| 3 | Table Size | 2150x3420mm | 2350x3920mm | 2850x3920mm | 2850x4920mm |

| 4 | X,Y,Z Traveling Positioning Accuracy | 0.01/300mm | |||

| 5 | X,Y,Z Repositioning Accuracy | 0.03mm/300mm | |||

| 6 | Table Surface | T-slot and vacuum working table | |||

| 7 | Frame | Heavy Steel Tube Structure | |||

| 8 | X,Y Structure | Rack and pinion Drive,Hiwin Rail Linear Bearings | |||

| 9 | Z Structure | Hiwin Rail Linear Bearings and Ball Screw | |||

| 10 | Max. Power Consumption | (Without Spindle)5.8KW | |||

| 11 | Max. Rapid travel Rate | 50000mm/min | |||

| 12 | Max. Working Speed | 30000mm/min | |||

| 13 | Spindle Poweer | 9.0KW air cooling spindle ,ATC spindle | |||

| 14 | Spindle Speed | 0-18000RPM | |||

| 15 | Drive Motors | Servo motor | |||

| 16 | Working Voltage | AC380V/50/60HZ,3PH(Option:220V) | |||

| 17 | Command Language | G Code | |||

| 18 | Operation System | Syntec control system | |||

| 19 | Computer Interface | USB/ Ethernet | |||

| 20 | Flash Memory | 512M | |||

| 21 | Collet | ER32 | |||

| 22 | X,Y Resolution | <0.03mm | |||

| 23 | SOftware Conpatibility | Type3 / Artcam software | |||

| 24 | Running Environment Temperature | 0-45 Centigrade | |||

| 25 | Relative Humidity | 30%-75% | |||

| 26 | Packing Size | 3670x2270x2080mm | 4170x2270x2080mm | 4170x2270x2080mm | 5170x2270x2080mm |

| 27 | N.W. | 1250KG | 1500KG | 1750KG | 1950KG |

| 28 | G.W. | 1450KG | 1750KG | 2050KG | 2250KG |

Basic Features

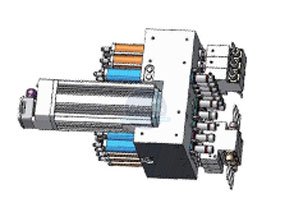

9.0KW ATC spindle + a cutting saw

9.0kw ATC spindle for engraving and cutting normal materials. A cutting saw with 250mm diameter can cut maximum 120mm thickness sheet at high speed.

Auto tool magazine

8pc linear type auto tool changers, ISO30. Don’t need to change tools manually when machine works, improve efficiency a lot. More tool changers is available.

Syntec controller

The system stability is very good, the man-machine operation is friendly, easy to learn and operation, powerful function.

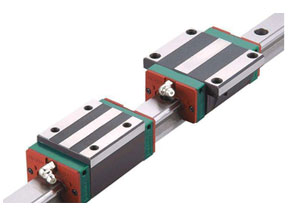

HIWIN Guide rails

Rail works with slider ,drive the machine move ,with good bearing capacity.

Delta servo motor

Faster speed with signal feedback . Low heat radiation . Run smoothly at ultra-low speed. Reduce the vibration ,avoid oscillation . Efficient torque enhancement.

5.5kw air vacuum pump

The air between the workpiece and the worktable surface is extracted to form a negative pressure, so as to achieve the purpose of fixing on the work table.

Options

Boring unit

Ensure machining accuracy and save machining time

Carousel tool changer

Fast speed, more convenient, save processing time, high control accuracy

Mist spray cooling system

Reduce the heat of material and workingtool bits .suitable for metal processing .

applications

Furniture: wooden doors, chairs,cabinets, stairs,computer tables, sewing machine, musical instruments

Plate processing: insulation, plastic and chemical, the PCB, move the car body, bowing, track, stars anti-special board, epoxy, resin, ABS, PP, PE, and other carbon mixture

Decoration industry: acrylic, PVC, MDF, artificial stone, plexi-glass, plastic, and copper and aluminum and other soft metal plate engraving and milling cutting.

Talán a következő termékek is érdekelhetik

En

En Cn

Cn Fr

Fr Ru

Ru